Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Streamlining Optical Fibre Production with the Advanced Optical Fibre Diameter Analyser

Blog Article

Exactly How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes represents a considerable advancement in quality assurance methods. By offering real-time, specific measurements of Fibre sizes, this technology resolves the crucial need for uniformity in production standards. With its capacity to quickly identify deviations and punctual corrective actions, the analyser not just improves item dependability yet additionally adds to general functional effectiveness. As markets increasingly prioritize high quality and conformity, recognizing the full influence of such innovations comes to be necessary. What implications could this have for the future of Fibre production?

Relevance of Fibre Diameter Dimension

Exact measurement of Fibre Diameter is critical in the field of optical Fibre innovation, as it straight affects the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, attenuation, and total transmission effectiveness. Accuracy in gauging Fibre Diameter ensures that the optical buildings are preserved within defined resistances, which is vital for optimum signal stability.

Variants in Fibre Diameter can lead to raised losses because of scattering and modal diffusion, influencing the top quality of information transmission. In high-speed communication systems, such discrepancies can cause considerable degradation of signal high quality, leading to data mistakes and lowered performance. Furthermore, regular Fibre Diameter is vital for compatibility with adapters and splicing technologies, which are important parts of Fibre optic networks.

Quality control processes in Fibre manufacturing greatly count on exact Diameter dimensions to make sure conformity with sector standards. By carrying out durable dimension strategies, makers can boost item dependability, lessen waste, and enhance total system efficiency. Thus, the significance of Fibre Diameter dimension can not be overstated, as it serves as a foundation in the advancement of optical Fibre technology and its applications in modern-day communication networks.

How the Analyser Functions

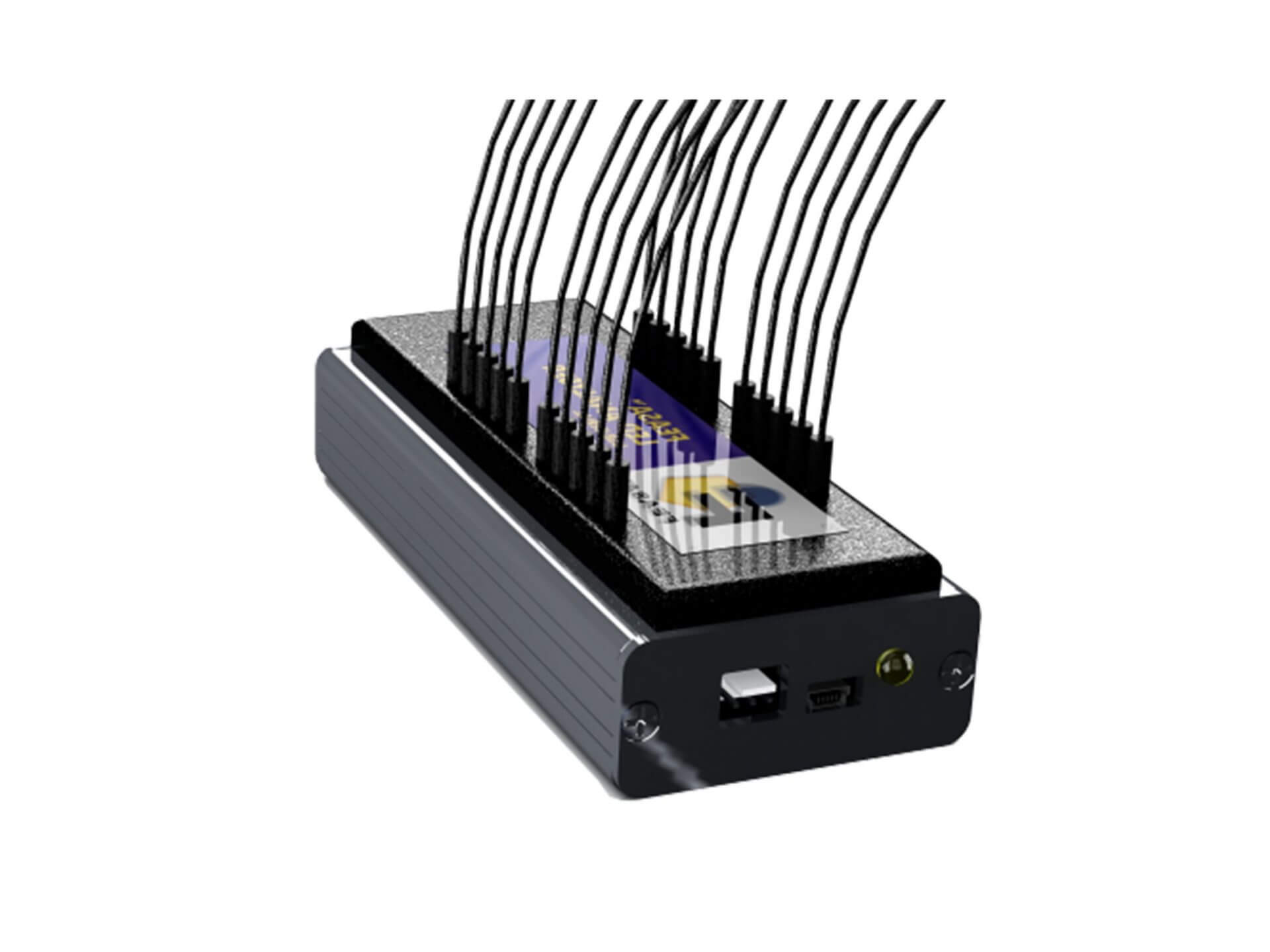

The reliable dimension of Fibre Diameter depends on innovative analytical methods that guarantee precision and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser technology and progressed photo handling formulas to accurately examine the Diameter of fibres as they are created

Initially, a laser beam is routed at the relocating Fibre, creating a cross-sectional darkness. The analyser catches this shadow using high-resolution video cameras positioned strategically along the assembly line. The caught images are after that processed in real-time to establish the Fibre's Diameter with phenomenal precision.

The system makes use of advanced algorithms that account for numerous variables, including variations in light strength and ecological problems, to boost measurement reliability. It can find minute modifications in Diameter, such as fluctuations that might take place during the production procedure.

Additionally, the analyser is qualified of handling numerous fibers at the same time, raising throughput without endangering precision. By supplying instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays a crucial role in maintaining rigorous quality assurance requirements, ensuring that the end product satisfies market specifications and consumer demands.

Advantages of Real-Time Monitoring

While conventional methods of keeping track of Fibre Diameter often entail time-consuming post-production checks, real-time tracking considerably boosts the effectiveness and top quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive technique enables suppliers to identify deviations in Fibre Diameter as they happen, instead than waiting up until production is complete to evaluate quality

By continuously determining the Diameter during production, suppliers can make certain that the fibres satisfy strict requirements, resulting in minimized variability and improved uniformity. Real-time monitoring also enables instant rehabilitative actions to be taken, reducing waste and protecting against malfunctioning fibres from getting in the supply chain.

Additionally, this modern technology promotes boosted data collection and analysis, providing understandings right into manufacturing trends and possible locations for renovation. Such data-driven decision-making empowers suppliers to maximize processes and preserve high standards of quality assurance.

Furthermore, real-time tracking cultivates a culture of continual renovation within the manufacturing atmosphere. Staff members are much more involved when they can see the influence of their operate Discover More in real-time, bring about increased responsibility and a dedication to quality. Overall, the application of real-time monitoring systems in optical Fibre production equates to exceptional product top quality and enhanced consumer fulfillment.

Effect On Manufacturing Performance

Implementing optical Fibre Diameter analysers considerably boosts manufacturing efficiency by simplifying the manufacturing process. These tools assist in constant surveillance of Fibre Diameter, allowing manufacturers to identify discrepancies in real-time. find out this here By determining inconsistencies quickly, manufacturing lines can be readjusted rapidly, lessening downtime and lowering the possibility of creating faulty products.

Additionally, the combination of these analysers right into the production process makes it possible for much better source allowance. With accurate Diameter dimensions, drivers can enhance product use, guaranteeing that resources are not squandered on problematic fibers. This accuracy likewise adds to much less revamp and scrap, ultimately reducing manufacturing costs.

The automation supplied by optical Fibre Diameter analysers minimizes reliance on hands-on assessments, which are susceptible and frequently taxing to human mistake. Because of this, workers can concentrate on more calculated tasks, improving total efficiency.

Furthermore, the data created from these analysers can notify process enhancements and assist in better decision-making. By examining fads in Fibre Diameter variants, manufacturers can implement proactive steps to boost manufacturing strategies and maintain consistent quality. In recap, optical Fibre Diameter analysers play a vital function in boosting manufacturing performance, leading to higher quality outcome and boosted earnings.

Study and Success Stories

Across various markets, case studies highlight the transformative effect of optical Fibre Diameter analysers on production procedures. One famous example is a leading telecoms business that encountered challenges with irregular Fibre sizes, bring about enhanced denial prices. By integrating an optical Fibre Diameter analyser, the firm accomplished real-time monitoring of Fibre measurements, causing a 30% decrease in problems and substantial price financial savings.

In addition, a study establishment concentrating on advanced products used optical Fibre Diameter analysers to fine-tune their experimental processes. The analyser's capacity to give thorough understandings right into Fibre consistency enabled the development of innovative products with better efficiency features.

These success stories underscore the essential role of optical Fibre Diameter analysers in boosting high quality control, boosting production performance, and driving development across varied industries.

Final Thought

In conclusion, the Optical Fibre Diameter Analyser plays a crucial function in enhancing top quality control within Fibre production. As shown via various situation researches, the analyser proves necessary for accomplishing remarkable product high quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers permitted for rigorous high quality control, ensuring that the generated fibres fulfilled exacting sector standards.In verdict, the Optical Fibre Diameter Analyser plays a pivotal function in improving quality control within Fibre production.

Report this page